Cutter Specialized In Cutting Stainless Steel

The difficult to machine materials among them, such as stainless steel which with high content of Cr and Ni, Cr, can improve the strength and toughness of stainless steel, but it also increases the bonding tendency of stainless steel and cutter; Ni may apply a stable organization, but large plastic of organizations easily lead to hardening. Use tungsten cobalt carbide cutting tools to process, but the result is unsatisfactory.

BW cutter specialized in cutting stainless steel, which is made of the newest advanced metal ceramics, is developed for machining difficult material contenting Nickel more than 18% . This series of cutter has better flexural strength and wet cutting and it may get superior resistance and stability during machining. Its tool life is 5 times more than tungsten carbide cutter when cutting stainless steel with excellent performance.

Cutting characteristics:

- Have a stable cutting performance (thermal shock resistance enhancement) in wet cutting.

- Better performance than the past types of nano tungsten carbide in anti-abrasion and anti-exhaustion. Material properties.

Advantages:

- the effect of self-sharp and regrinding for cutting edge

- stable chemical properties

- no infiltration effect on the blade

- other parts of cutter material transferred which can be neglected

- Co for metal bonding material, replacing the mixture of Ni and Co, pollution-free

- higher processing security

- broader applications

- greater ability to maintain the surface finish and accuracy

- strengthen intermittent processing capacity

Cutting test for end mills:

Cutting method: no oil, water, cutting oil added (dry cutting) and under general room temperature

| Material | Stainless Steel |

| Material Spec | 100*100mm |

| Rotation Speed | 5000 |

| Feed Rate | 600 |

| Total Cutting Length | 850mm |

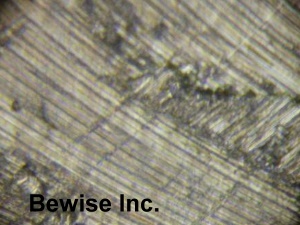

Tool mark metallographic photo of work piece after high speed steels

NO.1 Cutter - 2 Flute End Mills/HSS

Tool mark metallographic photo of work piece after high speed steels

NO.2 cutter - 4 Flute Corner Radius End Mills/ Solid Carbide - Nano Micro Grain

Tool mark metallographic photo of work piece after high speed steels

NO.3 cutter - 4 Flute End Mills/ Solid Carbide - Super Micro Grain

Tool mark metallographic photo of work piece after high speed steels

NO.4 cutter - 4 Flute Corner Radius End Mills/ Solid Carbide - Micro Grain

Dry cutting test of metal ceramic cutter:

Cutting method: no oil, water, cutting oil added (dry cutting) and under general room temperature

Spec: Dia 8mm x R0.5 x Flute 20mm x Overall 60mmL x Helix 35°

| Material | Stainless Steel |

| Material Spec | 100*100mm |

| Rotation Speed | 5000 |

| Feed Rate | 600 |

| Total Cutting Length | 3400mm |

Metallographic photo of tool mark after metal ceramic cutter cut at beginning

Metallographic photo of tool mark after metal ceramic cutter cut 3400mm

Cutting test for metal ceramic end mills

News

- Cutting fiber-reinforced composite material - Part I

- Principles of Difficult Cutting Material

- Rougher cutters and wave groove milling cutters

- Slitter Knives

- Cutting test for metal ceramic end mills

- Applied tool for automotive industry

- Characteristics of Tungsten Carbide Cutter

- Discontinuous or Segmental Chips

- General cutting tool material

- Production process of cutting tools

- Cutter wear and life

- The super-hard thin film coating material

- Anticlockwise milling and clockwise milling

- Cutting Reference Data for End Mills of Various Materials

- The cutter materials and their contrast

- The cutting tool for hardening material above HRC50

- How to choose woodworking cutters?--part2

- How to choose woodworking cutters?--part1

- Cutter selection Part-2

- Cutter selection Part-1

- What is cutting tool?

- Characteristics of precision miniature cutting tools

- Plain Milling Cutter,End Mill,Side Milling Cutter,Face Milling Cutter

- What’s the difference among tungsten carbide, tungsten steel cutter, and super hard alloy cutter?

- How to calculate the clamping length of the CNC lathe clamp for cutting tools?

- Selections and types of End Mills

- Definition and types of hard metal and difficult material

- How do end mills choose and judge working conditions?

- PCD circular saw blades

- 3 Jaw Adjustable Oil Filter Wrench

- Plastic Power Inductor Machine

- ZrO2 Introduction

- Common mode Choke Inductor machine

- Cutting tool-90° Step Drill

- Cutting tool-Circular saw with metal ceramic blade

- 3000°C Graphite crucible

- Cutting tool-Diamond Product

- SiC Granulation molding machine

- Cu75Ga25, Cu40In60 Target Material

- High-Entropy Alloys

- 8 flute T type Single-Angle Chamfering Cutter

- CNC 5-axis machining technology-Shoe Mold

- Grinding up to nano powders

- Cutting tool-Sharp Top Single Flute Drilling Cutter

- Cutting tool-Precise Engraving Milling Cutter

- Cutting tool-PCD Inserts

- Inductor Powder Compacting Press

- Cutting tool-Electroplated Diamond tools

- Cutting tool-Acrylic Cutting Tools

- Compound Sharpener

- BW carbide cutter cut carbide material

- Cutting tool-Staple Cutter

- Cutting tool-Diamond cutter in grooving floors