- Home

- News

News

Cutting fiber-reinforced composite material - Part I

Update:2012/03/26

The composite material,as implied by the name, is a combination of two or more materials. Generally speaking, it is constituted by a base material (matrix) and a reinforcement material (reinforcements)...

Principles of Difficult Cutting Material

Update:2012/03/19

The materials of high strength with poor workability or high hardness metal, makes the cutting tool life is shortened, or the volume crumbs, chip breaker difficulties, or machining surface quality is poor, or a combination of several above phenomena, therefore such materials are called difficult cutting metal materials. ...

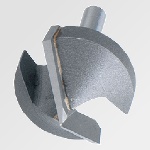

Rougher cutters and wave groove milling cutters

Update:2012/03/05

The general rougher cutter reduces the cutting deformation from broadband chip into several narrower chips, which may improve the formation of curl and chip removal situation during the milling process ...

Slitter Knives

Update:2012/11/08

Strength and dimensionally accurate bevels enable excellent cut and burr-free razor sharp edges. We use only high quality solid steel and high speed steel in the manufacturing of our slitter knives to accrue greater consistency and stable cutting. To meet your demand of wide variety material cutting, we offer large variety of material.

Cutting test for metal ceramic end mills

Update:2012/09/07

BW cutter specialized in cutting stainless steel, which is made of the newest advanced metal ceramics, is developed for machining difficult material contenting Nickel more than 18% . This series of cutter has better flexural strength and wet cutting and it may get superior resistance and stability during machining. ....

Applied tool for automotive industry

Update:2012/02/28

Highly efficient cutting tech and tools have become the key technologies of the automotive manufacturing process. The new cutting craft like high speed cutting, dry machining, hard machining and new cutting tech has been changing ....

Characteristics of Tungsten Carbide Cutter

Update:2012/02/20

Pure carbide contains carbides and cobalt only, with best strength and anti-wear characteristics, and its strength and abrasion resistance will be reduced by adding any other substances, it is usually used for cutting cast iron and non-ferrous metal materials. But the pure carbide cannot endure high temperature, its scrap will stick on the cutter blade face easily during high heat, which causes the flank depression by its diffusion....

Discontinuous or Segmental Chips

Update:2012/02/13

Work piece will happen internal plastic deformation after machining by cutters. The degree of plastic flow directly affects the chip types. The basic forms include three types: discontinuous chip, continuous chip and continuous chip amass of edge incision.....

General cutting tool material

Update:2012/02/07

Characteristics of tool material is the major factor to influence the surface quality after machining, efficiency, and tool life. It affords the direct cutting work during machining. Mostly the cutting performance depends on the materials of cutting edge, the geometric parameters and the choice of the tool structure and design. ...

Production process of cutting tools

Update:2012/02/02

The main component is the micro powder of tungsten carbide powder is (WC, TiC), cobalt (Co) or nickel (Ni), molybdenum (Mo) as a binder, mix them under certain volume. After mixing granulation then take the raw material powder into the mold for stamping molding, to make it with the similar hardness to chalk...

Cutter wear and life

Update:2012/01/10

Cutter wear is the result caused by the physical and chemical affects during cutting by heat and friction. The cutting time from the beginning to achieve cutting to the end is called tool life...

The super-hard thin film coating material

Update:2012/01/01

Depositing TiC, TiN, TiCN, Al2O3 ... hard ceramic coating with a few μm on carbide tool is more suitable for high speed machining than WC series, and with higher feed strength than ceramic. There are two depositing ways -- CVD (chemical vapor) and PVD method (physical vapor method).

Panticlockwise milling and clockwise milling

Update:2011/12/28

Milling is one of the most common and most widely used processing methods, and for roughing milling of the various structural components and fine milling is almost by end milling. There are two ways, clockwise and anticlockwise milling, according to the cutting direction. The movement of the cutting edge and work piece is ...

Cutting Data for End Mills of Various Materials

Update:2011/12/19

Effective working solution depends on correct cutters, operation method, and technology.Usual cutting conditions and major influence factors of CNC machines. ....

The cutter materials and their contrast

Update:2011/10/12

This list includes eight cutter materials and their contrast as below:Mono Diamond、PCD(CO PCD)、PCD(si PCD)、PCBN、Si3N4、SiC)、WC) and Steel. ....

For hardening material above HRC50?

Update:2011/10/05

There are higher requirements and more difficulties for many hardened molds. Hence general carbide cutters cannot reach such request of accuracy. Therefore, it should pay more attention to selection of cutting tools for hardened material. Since hardening material which HRC is above 50, with higher hardness, the carbide cutter is ....

How to choose woodworking cutters?--part2

Update:2011/09/28

Selection of woodworking cutters:1.identify the main technical parameters of the cutter.2. Choose the structure type of cutter.3. The choice of the cutter rotation direction.4. Selection of cutting amount .....

How to choose woodworking cutters?--part1

Update:2011/09/28

There are hard wood and wood composites material. And it may be divided into soft wood, hard wood and modified wood; wood composite materials, including plywood, laminated veneer lumber, particleboard, oriented strand board, wafer board, gypsum particle board, cement particle board, hardboard.....

Cutter selection Part-2

Update:2011/09/22

There are square end mill, side cutter, angle cutter, shape cutter, end mill, T-slot cutter, semi-moon key seat cutter, dovetail cutter , as well as face milling cutter.....

Cutter selection Part-1

Update:2011/09/20

Only correct type and cutting edge may do a good job for milling work. Popular end mills include flat cutter, side cutter, face milling cutter, milling cutter, end mill, sawing, and milling cutter. Its characteristics is....

What is cutting tool?

Update:2011/09/13

There are lots of metal products around us in our life, but we all know how they are produced? There are many processing methods to make metal, cutting is the major one among them. ....

Characteristics of precision miniature cutting tools

Update:2011/09/08

Four major cutting method:Precision micro turning,Precision micro milling,Precision micro fly cut,Precision micro drilling.There are precision micro turning tools, flat end mills, ball end mill, throwing cutter, and drills according to these applications. The working conditions, friction, impact, and .....

Characteristics of cutting tools

Update:2011/09/06

Plain Milling Cutter is the most commonly used tool in a horizontal milling machine. Plain Milling Cutter’s shape is like disc or cylindrical, which has blades on the outer circumference of the cutter for milling the plane which parallel.....

Tungsten steel cutter&super hard alloy cutter

Update:2011/09/05

In fact, they are saying the same tool. The component is tungsten carbide (WC) and took part in the P type, M type, and K type. Micro grain carbide tool is made of tungsten carbide and adding some ......

Length of the CNC lathe clamp for cutting tools?

Update:2011/09/02

Generally, when working project includes face cutting, outer cutting, and inner cutting three ways and rough or heavy cutting, of course we will try to extend the clamping length, and calculate the suitable pressure.......

Selections and types of End Mills

Update:2011/09/01

There are many kinds of end mills, which with wide range of applications. It can be divided into the following three categories: 1. Thimble cutter for machining plane. 2.Carbide cutter for......

Definition of hard metal and difficult material

Update:2011/08/25

Hard Material: Generally it means higher hardness of the steel material which can be cut, such as alloy steel, die steel. . . etc.Applicable to the cutters with coating, such as: TiAlN, TiN. .....

How do end mills choose ?

Update:2011/08/25

In recent years, machining center spindle is more and more speedy. For fitting the requirement of high speed machining on high hardness and strength materials and also prolonging mold life .....

PCD circular saw blades

Update:2011/08/08

Designed for wood geometry, good for cutting both hard and soft wood or compound material. It can extend tool life, reduce wear, and get good cooling result. General saw glade of other brands doesn’t proceed some processes.....

3 Jaw Adjustable Oil Filter Wrench

Update:2012/01/18

3 Jaw Adjustable Oil Filter Wrench's characteristics:New design ensures oil filter is gripped on-center to avoid slippage.Special design of triangle grip is easy removed and replaced, it coated of artificial diamond.......

Plastic Power Inductor Machine

Update:2011/08/05

It is different from previous powder compression machine, plastic power inductor adopts wet feeding way and shaping by pressure and heat.The benefit is that pressure load can be reduced a lot to shape. And the finished product made.......

ZrO2 Introduction

Update:2011/08/05

Pure ZrO2 is a white solid. It may appear gray or light yellow if it contains some impurities. It can display other colors as it adds developer. There are three zirconium crystal forms: monoclinic, tetragonal, and cubic.Zirconium material is with many good characteristics including high hardness, high strength.......

Common mode Choke Inductor machine

Update:2011/06/11

BW supply and organize full production lines according to demand of Common Mode inductor producing. Common Mode Inductor whole production line: automatic winding two-lane special equipment, inductor-based visual positioning assembly machine, inductive type high-speed assembly machine, and.......

Cutting tool-90° Step Drill

Update:2011/05/15

Step drill, the related accuracy in manufacture process is the most important factor for cutting quality. If the precision isn’t controlled well, it will cause hole too rough and even caused reject of work piece. Not only geometry, specification, accuracy, and surface quality, but also the drill volume are important points for the cutting quality of step drill........

Cutting tool-Circular saw with metal ceramic blade

Update:2011/04/15

BW’s advanced metal-ceramic brazed circular saw has better flexural strength in machining high hardness alloy which content 18% up of Ni and more superior damage resistance and stable quality in wet machining than HSS saw......

3000°C Graphite crucible

Update:2011/03/15

Graphite used mainly on of metallurgy, specialized in producing fire-resistant materials, such as graphite crucible, blast furnace lining, heat preservation medicinal preparation and carbon agent. The melting point of graphite is higher, gasification till 4500 ° C. ......

Cutting tool-Diamond Product

Update:2011/02/15

BW develops PCD diamond cutting tools through long time researching. The cutter for tongue and groove wood flooring may extend long machining time and tool life. The finished products, wood flooring, achieve good quality about easy to settle and superior stability with adaption.......

SiC Granulation molding machine

Update:2011/01/15

SiC Granulation molding machine stirs the main axle by using oil pressure power which torsion is above 5 times than general pellet machines.This machine meets the CGMP requirements.The resolver of the vertical type super mixer, which can save 10% than general mixer, may reduce the production cost and increase the economic efficiency.The vertical type super mixer leaf and chopper both are located at the cover of barrel........

Cu75Ga25, Cu40In60 Target Material

Update:2010/11/15

- Characteristics:

CIGS thin film solar cell precursors - Specifications:

Target diameter:3"and 4" Cu75%Ga25%,Cu40%In60% - Application:

Apply vacuum melting production to make target compound of CIGS thin film solar cells......

High-Entropy Alloys

Update:2010/10/15

- Characteristics:

High-Entropy alloys is a new design concept of alloy, which use multi major composition instead of traditional single main ingredient. It has large difference than traditional one. - Target material diameter:

3"and 4" - Application:

Good for traditional industries which with huge requirements, endurable mold, 3C electronic mold , and high speed cutting tools.

8 flute T type Single-Angle Chamfering Cutter

Update:2010/09/15

- Product:High Precision 8 flute T type Single-Angle Chamfering Cutter

- Specification:

Custom order according NAS standard. - Characteristics:

Apply to cut aviation difficult material of alloy. For fitting the high accuracy request, the tolerance range for each flute of cutter is as the form below.

CNC 5-axis machining technology-Shoe Mold

Update:2010/08/15

Shoe mold, usually refers to mould of sports shoes, sandals, slippers, and rubber shoes. Sport shoes is the main among all. Mold made from some processes like injection, extrusion, blow, casting, forging, smelting, stamping, and other methods to get the request mold and tool. It needs ......

Grinding up to nano powders

Update:2010/07/15

Silicon Carbide now is often used as non-oxide ceramic materials. Because it has better hardness, heat resistance, oxidation resistance, corrosion resistance and thermal conductivity than general ceramic materials. Hence it is widely used in structure of mechanical engineering and seal part of chemical engineering......

Cutting tool-Sharp Top Single Flute Drilling Cutter

Update:2010/06/15

Specialized in working some materials like acrylic, plastic, and related ones. And work custom order according to special request. Single flute may speed the working period and shorten the time.

Cutting tool-Precise Engraving Milling Cutter

Update:2010/05/15

Specialized in cutting soft material like acrylic, plastic board, wood plate, …etc for engraving tiny picture and word. We may make custom order according to your special request.......

Cutting tool-PCD Inserts

Update:2010/04/15

There are hundreds of cutters designed for alloy wheels. Various cutters specialized for different type of wheels are well-designed. Regarding the pin hole problem of c asting which happens in diameter under 1mm, it may be improved by using PCD cutters. We can make ........

Inductor Powder Compacting Press

Update:2010/03/15

Inductor is caused by the magnetic field generated by electric currents according to Ampere's law. To add Inductor to a circuit, electronic components called inductors are used, typically consisting of coils of wire to concentrate the magnetic field and to collect the induced voltage.......

Cutting tool-Electroplated Diamond tools

Update:2010/02/15

This type of CBN cutter is specialized for grinding glass parts. The controller should have pecking function to avoid bad chip removal, which is related to CBN particles since the particle size is in proportion to the roughness of surface. We should say “grinding glass” instead of “cutting glass.”The spindle......

Cutting tool-Acrylic Cutting Tools

Update:2010/01/15

The width of tip bottom is 0.10~0.25mmmm. The surface of work piece is very exquisite, no blunt and any cutting trace, no acrylic remnants left in the flute gap, and the design of central point is very special........

Compound Sharpener

Update:2009/12/15

Compound grinder may assemble two functions, re-grinding end mill, drill, tap, or carbide rod. For End Mill+Drill Sharpener, it apply to re-sharpen dia 2mm – 13mm, of square end mills with flute 2,3, 4, and 6 to make cutter sharp again.......

BW carbide cutter cut carbide material

Update:2009/11/15

BW develop new type CNC cutters specialized in cutting carbide work piece, HV550°. It is difficult material. We design special geometry, which is different from traditional end mills. Since general end mills will be broken if it cuts carbide mould .......

Cutting tool-Staple Cutter

Update:2009/10/15

- Application:

- Anti-wear products

- Cutting tools

- Industrial cutter

- Electric conduction products

- Material: HSS or carbide material

Cutting tool-Diamond cutter in grooving floors

Update:2009/09/15

Bewise Inc. is an professional cutter manufacturer. We are experienced in researching wood cutting tool. Now we develop a new series PCD diamond cutter specialized in groove wood flooring which may improve the accuracy and stability of groove a lot. Wood floor factories focus .....

News

- Cutting fiber-reinforced composite material - Part I

- Principles of Difficult Cutting Material

- Rougher cutters and wave groove milling cutters

- Slitter Knives

- Cutting test for metal ceramic end mills

- Applied tool for automotive industry

- Characteristics of Tungsten Carbide Cutter

- Discontinuous or Segmental Chips

- General cutting tool material

- Production process of cutting tools

- Cutter wear and life

- The super-hard thin film coating material

- Anticlockwise milling and clockwise milling

- Cutting Reference Data for End Mills of Various Materials

- The cutter materials and their contrast

- The cutting tool for hardening material above HRC50

- How to choose woodworking cutters?--part2

- How to choose woodworking cutters?--part1

- Cutter selection Part-2

- Cutter selection Part-1

- What is cutting tool?

- Characteristics of precision miniature cutting tools

- Plain Milling Cutter,End Mill,Side Milling Cutter,Face Milling Cutter

- What’s the difference among tungsten carbide, tungsten steel cutter, and super hard alloy cutter?

- How to calculate the clamping length of the CNC lathe clamp for cutting tools?

- Selections and types of End Mills

- Definition and types of hard metal and difficult material

- How do end mills choose and judge working conditions?

- PCD circular saw blades

- 3 Jaw Adjustable Oil Filter Wrench

- Plastic Power Inductor Machine

- ZrO2 Introduction

- Common mode Choke Inductor machine

- Cutting tool-90° Step Drill

- Cutting tool-Circular saw with metal ceramic blade

- 3000°C Graphite crucible

- Cutting tool-Diamond Product

- SiC Granulation molding machine

- Cu75Ga25, Cu40In60 Target Material

- High-Entropy Alloys

- 8 flute T type Single-Angle Chamfering Cutter

- CNC 5-axis machining technology-Shoe Mold

- Grinding up to nano powders

- Cutting tool-Sharp Top Single Flute Drilling Cutter

- Cutting tool-Precise Engraving Milling Cutter

- Cutting tool-PCD Inserts

- Inductor Powder Compacting Press

- Cutting tool-Electroplated Diamond tools

- Cutting tool-Acrylic Cutting Tools

- Compound Sharpener

- BW carbide cutter cut carbide material

- Cutting tool-Staple Cutter

- Cutting tool-Diamond cutter in grooving floors

BW Project Case

- BW-Circular saw with metal ceramic blade

- 3D CNC machining technology of PP foam sheet

- Re-grind PCBN & Replace PCBN inserts plan

- Side Milling Cylinder Cutting Tool

- Cutting Wood Curtain Plate

- T Type Cutter Measurement Data

- Grinding up to nano powders

- PCD Inserts

- Electroplated Diamond tools

- Acrylic Cutting Tools

- Diamond cutter in grooving floors

Copyright (c) 2003 碧威股份有限公司 Bewise Inc. All Rights Reserved

TEL:(04)2471-0048 / FAX:(04)2471-4839

Head Office:No.200, Dadun 2nd St., Nantun Dist., Taichung City 408029, Taiwan

E-Mail:bw@tool-tool.com